THE BENEFITS OF MIXING PROPERLY

How to Mix Concrete

Concrete is a carefully developed combination of cement, aggregates, and water. These three elements, when accurately combined, result in a long-lasting product. Meticulousness in concrete manufacturing is important from the very beginning – starting with the amount of each type of material measured, all the way to the end with the mixing process. Well-mixed and measured, quality concrete will not crack or crumble and can stand the test of time, pressure, and the elements.

Does the process and method of mixing concrete affect the end result? The answer is: Yes. Mixing matters. How concrete is mixed is crucial to the performance of the finished product. So, how should concrete be mixed for optimum results? There are specially designed tools for mixing concrete. These tools range from hand-held professional mixers to large machine mixers. Whether the batch of concrete that needs to be mixed is small or large, the method of mixing matters.

Ingredients in concrete

Understanding how the ingredients in concrete work together will ensure proper measurement and thorough mixing.

Cement. The first ingredient that comprises concrete is cement. A chemical substance, cement, acts as a binding agent. It is usually incorporated into the concrete as a powder form and is rarely used on its own. Instead, it helps the water to bind to other ingredients like aggregates.

Aggregates. The second ingredient in cement are mineral substances like sand, rock or gravel known as “aggregates.” Aggregates ensure strength and provide the load-bearing capacity of concrete. Aggregates can vary in size, shape and consistency ranging in sizes as fine as sand, to stones as large as 40 millimeters. The larger the aggregate, the more stress the concrete can withstand. However, the larger the aggregate, the more sluggish the mix which is why mixing with the proper tools is so important. Aggregates make up the major portion of the mix of concrete; about 60-80%.

Water. A concrete mixture with gravel-sized aggregates will require a different water percentage than a concrete mixture with sand aggregate. Water is usually 10-15% of the concrete mixture. The percentage of water and the size of the aggregate both result in particular conditions that require unique tools.

What is the concrete’s purpose?

Another factor to understanding proper mixing of concrete is its intended use. Countertops, driveways, stamped concrete, patios, and even vertical concrete pillars are all examples of different uses for concrete that require different mixing methods and tools.

Questions to ask when mixing...

Strength. What is the required strength? Are there residential or commercial codes regarding the concrete’s strength for designated use?

Durability. What is the concrete’s durability? How long can it be expected to hold up?

Appearance. What is the appearance of the concrete? Is it decorative, smooth, stamped?

To recap, first understand the concrete’s composition – water and aggregate ratio. Secondly, determine the concrete’s desired use by asking questions regarding strength, durability and appearance.

How to properly mix concrete

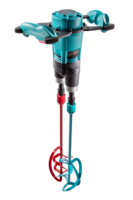

Choose your tool. The best and easiest way to mix any type of concrete regardless of its intended use or appearance is with a specially designed tool known as a “paddle mixer.” This tool is an ergonomically designed hand-held motor with a spindle and attachment at the end. This attachment can accommodate different paddle styles for the type of concrete being mixed. Paddle attachments are specific to concrete’s use and consistency as each one varies in the type of speed, force, and volume of air it mixes the material with. For example; larger aggregates, because of their size, require a powerful driving force – a more powerful machine. This will make the mix heavier.

A hand-held paddle mixer gives the user levels of control during mixing. Instead of over-mixing or exerting more energy than necessary; the paddle mixer allows the user to visually witness the incorporation of materials as opposed to an automatic mixer or large drum-shaped style mixer that is used for commercial and large-scale purposes. Automatic mixers are extremely helpful and have a big role to play in mixing (those will be discussed later on). Depending on the power of the motor, mixers can handle anywhere from 10 gallons and up to 24 gallons of material at a time. Choose a paddle mixer that is ergonomically designed, lightweight, and has high torque with low speed.

The combination of high torque and low speed is especially unique to professional mixers. They are larger and are naturally able to handle more material than a regular drill. Regular drills used for building and drilling have high speed and low torque. While many of them come with a mixing paddle attachment, the drill can burn out quickly. The mixing process takes significantly longer than drilling so the strain on the motor is increased. The resistance of the material slows down the motor considerably. This effort causes the motor to heat up and burn out. Paddle mixers are specially designed for mixing jobs of not only concrete but other mixed materials like resin, plaster, and mortar.

Choose your paddle. After choosing a paddle mixer – one that is ergonomical, has high torque and designed for the amount that needs to be mixed, choose your paddle. There are a variety of paddle attachments specifically designed for mixing. And different viscosities have different paddle applications in order to accomplish the perfect mixture.

Concrete, in all its various forms, needs a paddle that can handle mixing heavy, compact, and viscous textures. Consider the force that the paddle uses to mix. Also, consider the direction that the paddle is pulling the material– bottom to top. Finally, consider at what speed that the paddle is mixing the material – is it an optimum speed to dissolve lumps and process the mixture?

A paddle that incorporates the material from bottom to top will ensure that the lighter and finer ingredients are pulled through the entirety of mixture. The anti-gravity movement will pull up and then blend out water into the cement to properly incorporate and bind the mixture – much like the motion of a screw. This is much better for heavy material like concrete.

Choose your attachments. Once you choose a mixing drill and a paddle that is pertinent for the material, you need an appropriate sized bucket. Buckets should be about one-third larger than the maximum fill level. This minimizes the risk of any material being thrown out of the bucket during the mixing process.

Also, dust is to be expected when pouring materials into a bucket so it’s important to use a pair of goggles or consider using a dust extractor. A dust extractor is a small vacuum that can attach to the bucket or sits nearby and sucks up dust quickly before it escapes the bucket.

Process of mixing

If you are mixing concrete that is pre- bagged, the correct ratios of the material have been mixed. It is considered “ready-mixed” and all you need to do is add the correct amount of water.

First: The water should be added to the bucket and then the powder! Pour about 2/3 of the water into the bucket and then the premixed bagged material.

Second: Once you have begun mixing, you can add the remainder of the water. Water should be measured precisely. Do not “eyeball” it. Concrete that results in a durable product that can stand the test of time can only occur if the ratios of material are perfect. A watery concrete will compromise strength and cause cracking even if it makes the product easier to work with. Consider using an automatic water doser for precision.

Third: After the pre-mixed concrete bag has been poured into the bucket and the water is added, begin mixing with the chosen mixer and paddle until all the material is thoroughly incorporated. Using the appropriate mixing tool or machine ensures that all the individual components (water, cement, aggregates) are mixed evenly and as quickly as possible. Using a paddle mixer does not require force or brute strength. Simply holding it upright in the bucket and keeping it steady is enough to allow the paddle(s) to do their job. This is the only way to achieve maximum strength and durability of the mixture. Mixing cement by hand not only takes longer but puts the product at risk of compromise due to human error, lack of force, inconsistent speed and varying power.

Final: To recognize if the concrete is properly mixed and measured, look for concrete that isn’t too watery or too crumbly. It should have a shiny top layer and stay in place when pushed or pulled around as opposed to slumping over. Bagged, ready-mixed concrete should never be diluted with water after the mixing process is complete. Also, mixing of pre-bagged material should only be done with mechanical equipment. Mixing with a shovel by hand is a long, arduous process and does not guarantee consistent quality.

About Automatic Mixers

Automatic mixers, like large drum shaped concrete mixers, use power and magnitude to mix concrete. These are especially useful for jobs requiring mix amounts larger than 24 gallons.

Automatic mixers allow for increased productivity due to their speed, volume and hands-off set up. Many have settings that allow for automation like automatic shut-off when the concrete reaches the desired consistency. These large machines are equipped with built-in paddles that are designed to thoroughly incorporate the toughest of materials. However, not all automatic machines have paddle options like hand-held mixers do. Because of this automatic mixers should only be used when the paddle attachment matches the consistency of the material to be mixed.