Floor Leveling Mixer - LevMix

Flawless epoxy floor covering a hockey arena

Epoxy resin coating for 600 m2 (~718 sq yards) floor done in five hours. State of the art mixing technology plays a crucial role.

It is a real challenge to coat large floor areas with epoxy resin. This is because the processing time of synthetic resin is short and flaws such as clumps, scratches or unclean transitions in the coating are difficult or impossible to compensate for or correct afterwards. That is why Mirko Brasausky, project manager from the Lindner Group Germany, and his team precisely planned the necessary work steps before the flowing epoxy coating could be applied to the ice-hockey arena on 600 m2 of floor area of the grandstand walkways.

Sika Floor 264 N was the material used, a two-component flowing coating. This was enriched with 40% silica flour as a filler to achieve the necessary surface hardness. When using multi-component materials, the mixing process is crucial. On the one hand, the different components must be thoroughly and completely blended, while on the other hand these materials only have a short time span to work with them before they react with each other and the curing process begins.

This is why the processing team divided the work into teams. Four employees were busy distributing the material using a notched scraper and needle roller, while two others took care of the mixing process and the material transport. In this way, the required material could always be freshly delivered and worked. In this way, work could be done on a rolling basis and very quickly.

Application and distribution of the liquid mass with a notched scraper and needle roller

Thorough pre-mixing of the epoxy components with a dual-spindle mixer

The epoxy resin coating is poured out directly at the point of processing with the LevMix

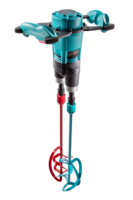

Achieving the optimal mixture with Collomix Xo 55 R duo and LevMix

Working efficiently and at the same time achieving the required quality requires a deliberate selection of the mixing technology to be used. Project manager Brasausky deliberately chose the combination of the dual-spindle Collomix hand-mixer and the liquid mass mixer LevMix by Collomix. Because the interplay of the powerful hand-mixer Collomix Xo 55 R duo with the LevMix not only ensures a quick and particularly thorough and clump-free mixing of the individual components, but also allows for a tremendous hourly throughput of material. In addition, this method of working relieves the employees of excessive physical strain. This combination of Collomix mixing technology not only saves time and money, but also protects the employees’ health.

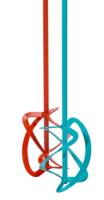

In this way, in the first step 23.7 kg (52.3 lbs) of resin and 6.3 kg (13.9 lbs) of hardener were mixed by hand with the Collomix Xo 55 R duo in the forced mixing process. This is because a uniform curing of the coating only occurs if the resin and hardener are homogeneously mixed throughout. So that no material splashes out of the bucket when mixing, the two mixing rods of the dual-spindle Collomix hand-mixer are used inverted - in this way, the mixing effect reverses and the material is drawn from the top to the bottom when mixing.

As recommended by the manufacturer, the two employees responsible for mixing repotted the reaction resin mixture - namely directly in the liquid mass mixer Collomix LevMix. To be on the safe side, they then mixed the material another three minutes in the device before adding nine kilogrammes of the powdery filler in the last mixing step and mixing it in for about two minutes. With its strong suction effect, the specially shaped mixing tool of the LevMix ensures a quick and clump-free mixing result with around 40 kilogrammes (88.2 lbs) of epoxy resin liquid mass.

Mixing, transporting, pouring out

Thanks to its carriage on castors, the finished mixed material can be conveniently transported right in the Collomix LevMix by just one person to the desired processing location while saving their back. Ideally balanced and with a side handle guide, the LevMix allows for a controlled and precise pouring out without straining the back.

In less than five hours, a flawless epoxy resin coating was finished on 600 m2 in the Landshut ice rink. The project manager Mirko Brasausky is completely satisfied. His plan worked: “In the end, we only spent about 30 seconds per square metre, which is great”.

Landshut ice arena grandstand walkways with finished epoxy floor coating